|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat Jul 14, 2012 1:35 pm Post subject: Hints for recycling furnace blowers . . . Posted: Sat Jul 14, 2012 1:35 pm Post subject: Hints for recycling furnace blowers . . . |

|

|

For years, I've used salvaged the guts of furnaces

to fabricate utility blowers for carpet drying,

workspace comfort, paint drying, etc. Dr.

Dee occasionally uses an energetic blower outdoors

when gardening in hot, low-wind weather.

These blowers are compact (motor mounts inside

the blower wheel) and often include some variable

speed options. They can be had for very little

from HVAC companies that change out old furnace

and a/c units. I just picked one up at a garage

sale for $20 where the owner had already mounted

it to a base and fitted with a carrying handle

and line cord.

Most DIY conversions I've seen in the wild do

not account for the fact that these blowers

are designed to push LOTS of air through a maze

of ducts. I.e., they are intended to do more

WORK than just move xx cubic feet of air per

minute. There is back-pressure of the duct work

to consider.

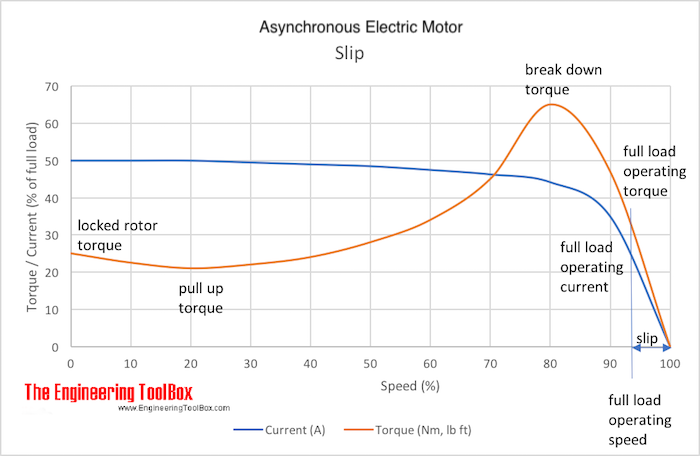

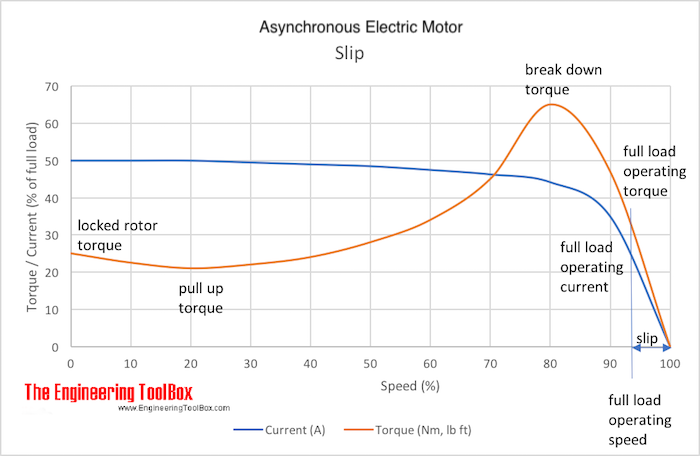

Referring to an exemplar speed vs. torque and

current curve . . .

We can see that there's a 'hump' in motor's torque

curve. We also see that rated operating characteristics

for the motor are on the right-side of that hump.

This means that for the motor to start up and

accelerate past the hump, the load on the

motor MUST be less than the 'break down'

torque else the thing won't make it up the

hump to it's operating point.

I knew that the blower I just bought was

exceedingly crippled in performance . . . it's

outlet port was wide open. Sure 'nuf. Got it

home, plugged it in . . . it did indeed move

some air. The snap-on ammeter read 4.5 amps.

But operated completely open loop, it gulped

in and tried to accelerate too much air.

I took a scrap of plywood and blocked off

about 1/3 of the outlet. The motor accelerated

up over the hump, rpm rose dramatically and it

really began to move some air!

I've added a permanent baffle adjusted so that

the motor draws about 3.5 amps. That's 'cause

I'm too lazy to take it apart and see if the

motor frame is marked with rated load current. If

I knew what the rated current was, I'd adjust

the baffle to achieve that current. In any case,

it now draws 1 amp less than when I bought it

and moves a great deal more air.

This is something to remember about induction motor

characteristics . . . they must be loaded well

down the right side of the 'hump'.

If any of you have ever used an induction motor

lawn mower, you may have experienced what one might

call 'motor stall' when pushing too rapidly into

tall weeds . . . the speed is loaded down to where

the motor tumbles down the front side of the hump.

You have to pull back and let it recover.

For you techno-nerds, max torque (or breakdown torque)

from an induction motor occurs at a 'slip frequency'

in the squirrel cage where inductive reactance is

equal to the DC resistance of the cage conductors.

It's 105 out there today . . . added air motion

in the shop will be welcome.

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1961

Location: Riley TWP Michigan

|

Posted: Sun Jul 15, 2012 4:17 am Post subject: Hints for recycling furnace blowers . . . Posted: Sun Jul 15, 2012 4:17 am Post subject: Hints for recycling furnace blowers . . . |

|

|

Blocking off the air inlet has the same effect: less current draw because the motor is doing less work. This is contrary to what one might expect because, in most applications, hindering the process requires more force to accomplish the task. Have you ever noticed that a vacuum cleaner motor speeds up when the air inlet is blocked?

Joe

[quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|